Natural Gas Installation

Natural Gas Installation

Yapıtek offers safe, economical, and long-lasting solutions in natural gas installation services in Kayseri with its expert staff and high-quality materials.

Natural gas installation is a critical process for ensuring safe, efficient, and cost-effective energy use in residential and commercial properties. Widely used for heating, hot water, and cooking, natural gas offers significant advantages when properly designed and installed. However, if the installation is not carried out in accordance with technical standards and safety regulations, it can pose serious risks. For this reason, natural gas installations must be performed by authorized professionals, following approved projects and current regulations to guarantee long-term safety and reliability.

What Is a Natural Gas Installation?

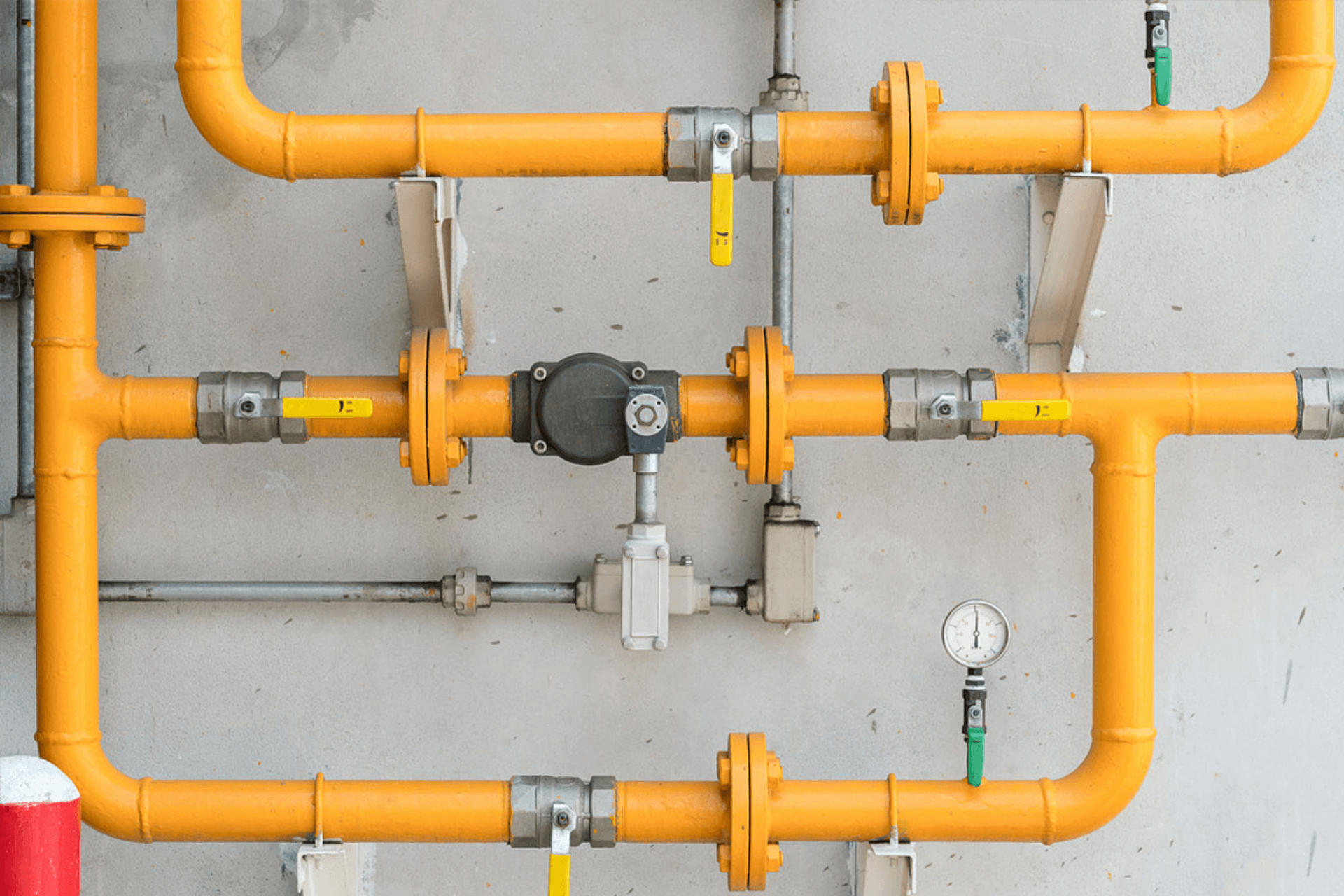

A natural gas installation is a system of pipes and connections designed to safely deliver natural gas from the main supply line outside a building to individual units and gas-powered appliances inside. This system includes the main riser line, internal piping, meter connections, shut-off valves, and appliance connection points. The primary goal of a natural gas installation is to transport gas in a controlled and leak-free manner. A well-planned system improves energy efficiency while minimizing the risk of accidents and gas leaks.

When Is Natural Gas Installation Required?

Natural gas installation is typically required during the construction of new buildings as part of the initial infrastructure setup. It is also necessary when converting properties that previously did not have access to natural gas. In renovated apartments, changes in kitchen or bathroom layouts, or relocation of gas appliances may require the existing installation to be modified or completely renewed. Each of these scenarios involves a technical process that must comply with official regulations and requires approval from the authorized gas distribution company.

The Natural Gas Installation Project Planning Process

Before starting any natural gas installation work, a detailed project plan must be prepared. During the planning stage, appliance locations, pipe routes, valve positions, and ventilation requirements are carefully determined. The prepared project is then submitted to the relevant natural gas distribution authority for approval. This step ensures that the installation is both legally compliant and safe. Installations carried out without an approved project may result in legal penalties and pose serious safety hazards.

How Is a Natural Gas Installation Carried Out?

Natural gas installation is performed by qualified technicians in accordance with the approved project. The process begins with connecting the main riser line to the unit and installing the gas meter. Steel or copper pipes are then used to create distribution lines leading to gas appliances. All pipe joints are securely connected using welding or certified fittings to ensure complete airtightness. Once the installation is complete, the entire system undergoes pressure testing and leak detection. Only after passing these tests is the installation deemed ready for use.

Materials Used in Natural Gas Installations

The quality of materials used in natural gas installations plays a crucial role in overall system safety. Commonly used materials include steel pipes, copper pipes, ball valves, flexible connection hoses, and certified sealing components. All materials must comply with national and international standards. Low-quality or non-compliant materials can lead to gas leaks, system failures, and serious safety risks over time. Therefore, material selection is one of the most critical aspects of the installation process.

Safety Rules in Natural Gas Installations

Strict adherence to safety rules is mandatory during natural gas installation. Pipe routes must remain accessible and visible, ventilation openings must be positioned correctly, and shut-off valves must be installed in easily reachable locations. The gas installation must never come into contact with electrical wiring, and appliance connections must follow manufacturer guidelines. Ignoring safety standards can result in severe consequences, including fire hazards, explosions, and property damage.

Inspections After Natural Gas Installation

Once the installation is completed, comprehensive leak and pressure tests are conducted to ensure system integrity. Specialized testing equipment is used to check all connections and pipe sections for gas leakage. After successful testing, the authorized gas distribution company performs the gas activation procedure. Using the system before official gas activation by authorized personnel is strictly prohibited and poses serious safety risks.

The Importance of Natural Gas Installation Maintenance

Natural gas installations require regular maintenance even after proper installation. Over time, fittings may loosen, valves may malfunction, or appliance connections may deteriorate. Periodic inspections allow these issues to be detected early and resolved before they become dangerous. Maintenance checks conducted before the heating season are particularly important, as they enhance safety, improve efficiency, and ensure uninterrupted energy supply.

Advantages of Professional Natural Gas Installation Services

Natural gas installation is not a task that should ever be attempted without proper training and authorization. Professional services ensure compliance with regulations, correct material usage, and safe application practices. Installations carried out by experienced professionals offer long-lasting performance and peace of mind. In addition, professional service providers offer technical support and rapid response in case of future issues, ensuring continuous and safe system operation.