Mechanical Installation

Mechanical Installation

Yapıtek offers safe, modern, and long-lasting solutions in mechanical installations in Kayseri with its expert team.

Mechanical installation systems form one of the most essential infrastructures that ensure buildings are comfortable, safe, and efficient to use. Covering vital applications such as heating, cooling, ventilation, plumbing, and fire protection, mechanical installation plays a critical role in residential, commercial, and industrial buildings alike. Systems that are not properly designed or implemented by unqualified teams may lead to excessive energy consumption, frequent failures, and serious safety risks. For this reason, mechanical installation works require technical expertise, detailed planning, and professional execution.

What Is Mechanical Installation?

Mechanical installation refers to the technical infrastructure that includes heating, cooling, ventilation, clean water, wastewater, natural gas, and fire protection systems within a building. These systems ensure indoor comfort while also providing a healthy and safe living or working environment. The main purpose of mechanical installation is to meet user needs continuously while using energy resources efficiently. A well-designed mechanical installation system reduces operating costs and significantly contributes to the long service life of the building.

Which Systems Are Included in Mechanical Installation?

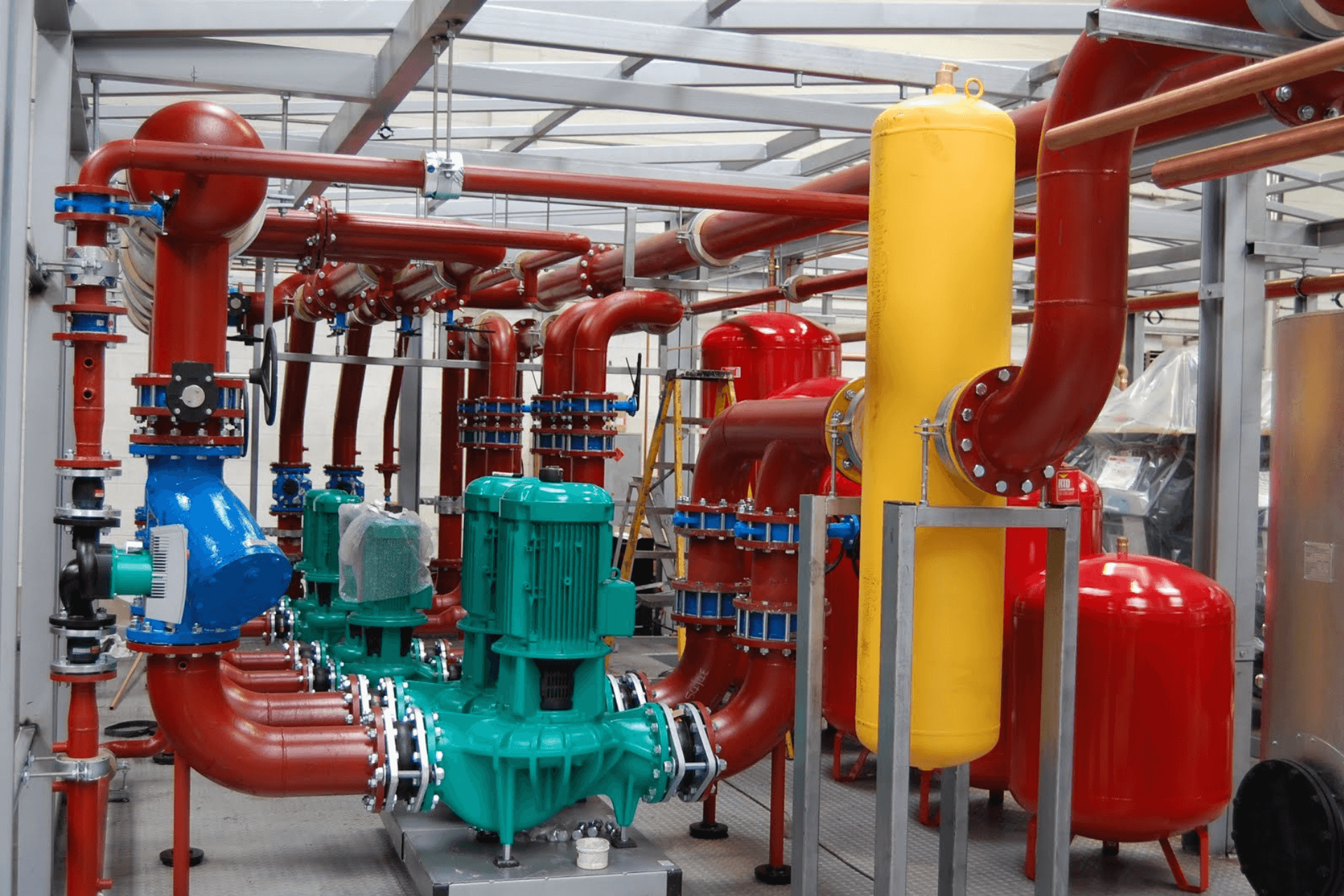

Mechanical installation covers a wide range of systems. Heating systems, cooling and air-conditioning solutions, ventilation systems, plumbing installations, natural gas pipelines, and fire suppression systems are among its core components. In addition, special process lines and pressurized systems used in industrial facilities are also considered part of mechanical installation. Each system is designed and implemented according to its specific technical requirements and operational purpose.

The Mechanical Installation Project Planning Process

One of the most critical stages of mechanical installation is the project planning process. During this phase, the building’s function, total area, occupancy levels, and energy demands are thoroughly analyzed. Heating and cooling load calculations are performed, appropriate systems are selected, and pipe and duct routes are planned in detail. All projects are prepared in compliance with applicable regulations and standards. Proper project planning forms the foundation for efficient, reliable, and long-lasting system performance.

How Is Mechanical Installation Implemented?

Mechanical installation implementation is carried out by professional teams in accordance with approved project designs. The process begins with the installation of piping, ductwork, and mechanical equipment. Insulation applications are then performed to minimize energy losses. After installation is completed, systems are tested and commissioned. During this phase, all installations undergo inspection, leak tests, and performance evaluations. Every step of the implementation process must strictly comply with quality and safety requirements.

Materials Used in Mechanical Installation Systems

The quality of materials used in mechanical installation systems has a direct impact on overall performance and durability. Steel, copper, and plastic pipes; valves and fittings; pumps; boilers; air handling units; and fans are among the most commonly used components. Insulation materials also play a vital role in improving energy efficiency. All materials must be certified and compliant with relevant standards to ensure safe and efficient long-term operation.

The Importance of Energy Efficiency in Mechanical Installation

Energy efficiency is one of the primary objectives of modern mechanical installation systems. Through proper system selection, accurate capacity sizing, and effective insulation practices, energy consumption can be significantly reduced. Energy-efficient mechanical installations not only lower operating costs but also contribute to environmental sustainability. Especially in large-scale buildings, energy-focused mechanical solutions provide substantial long-term economic benefits.

Maintenance and Inspections in Mechanical Installation Systems

Mechanical installation systems require regular maintenance and inspections after installation. Over time, components may wear out, connections may loosen, and system performance may decline. Periodic maintenance helps identify and resolve these issues at an early stage. Systems that are regularly maintained have longer service lives and lower risk of sudden failures. Maintenance activities also ensure that mechanical systems continue to operate at optimal performance levels.

Safety and Compliance in Mechanical Installation

Safety and compliance with standards are essential in mechanical installation applications. All systems must be designed and implemented in accordance with national and international regulations. Safety measures in natural gas and fire protection systems, in particular, are critical for protecting life and property. Standards-compliant installations fulfill legal requirements while also providing a secure environment for occupants and users.

Advantages of Professional Mechanical Installation Services

Mechanical installation is not a task suitable for individual or unqualified intervention. Professional mechanical installation services offer high-quality solutions through technical expertise, experience, and proper equipment usage. Systems installed by expert teams operate reliably for many years with minimal issues. In addition, professional services provide comprehensive support from project planning to maintenance, offering significant time and cost advantages for property owners and operators.